CanNeed Vietnam

Contact:

Trần Văn

Ý | Mr. |

I Sales Engineer I

========================

I cellphone I +84 989 199 111

+84 916 152 811

I email I vany@pitesco.com

vany.pitesco@gmail.com

I Sales Engineer I

========================

I cellphone I +84 989 199 111

+84 916 152 811

I email I vany@pitesco.com

vany.pitesco@gmail.com

Máy quét Seam tự động

CanNeed-Seam-X-On-line Seam-X-On-line On-line X-Ray Full Automatic Seam Scanner(non-destructive)

|     |

00:00

00:00

CanNeed-Seam-X-On-line X-Ray

Automatic Seam Scanner

(Non-destructive)

“Efficient, Cost saving, High Sampling frequency”

Equipment Outline:

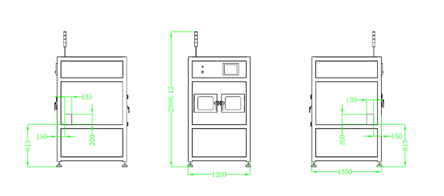

● Outline dimension:

● Production line distribution (Case one):

Technical data:

l Applicable for online in producing department; batch sampling test based on the preset time.

l Sampling interval: set the shortest time as sampling 12 cans/ batch in 1 minute

l Automatically input samples and measure samples, no need for human operation

l Accuracy:0.01mm

l 360-degree fully scan measurement, no blind spot detection

l Machine inspection beat: 5~8 second/PCS

l Load: production time calculation for 22 hours one day; Measuring capacity: 22(h) X 3600 (s) ÷ 5~8 (s) ≈10 K PCS/day. It’s a stable and reliable equipment to the continuous detection.

l Adopts closed loop control. The seam structure data of each can is separately corresponding to the chucks of seamer. Able to track the chucks corresponding to the unqualified products, saving a lot of time to find out the problems and adjust the seamer.

l Automatically get rid of the inferiors.

Measuring Process:

Take samples from the online signal automatic production line

Transport samples to the detection entrance

Automatic sampling to the rotating disk positioning Automatic sampling to the rotating disk positioning

Adopt non-destructive X-ray to go through the required inspection stations

360-degree fully scan measurement and take figures

Images can be auto analyzed by software Images can be auto analyzed by software  Qualified products Qualified products

Analyze data to the server

Analyze the status of seamer according to the data report

Inferiors Inferiors

Seam-X-On-Line Software features

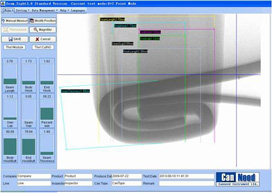

1) The seam overlap and tightness can be measured at the same time, 10 Measuring Items: Seam Length, Body Hook Length, End Hook Length, Overlap Length, Seam Gap, Overlap Rate, Body Hook Lapping Rate, End Hook Lapping Rate, On-screen Seam Thickness and Tightness

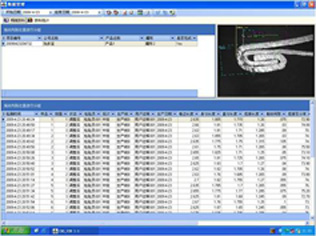

2) Report format can be customized, flexible for different report styles of different companies

3) Software adopted data base management system, measurement results and images are saved in the data base, users can facilitate inquires

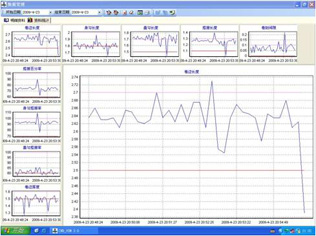

4) Graph chart statistic function, automatically analyze and compare the measurement results

5) Users can review or re-measure the saved projects at any time

6) Data can be exported as an Excel file

7) Predefine various qualification standards, can judge and warn automatically whether the results are qualified in every measure

8) Measurement results and label lines can be marked directly on the image, results will be also displayed in corresponding field on the screen

9) Seam image can be printed and stored, facilitate communication with the production department or canning factories, no need to retain the sample cans

10) Provided with calibration piece, users can calibrate at any time and set the calibration password

Seam Monitor development history:

|

Không có nhận xét nào:

Đăng nhận xét